Introduction

In digital design, color mode selection directly impacts final output quality. Adobe Photoshop’s RGB and CMYK modes serve distinct purposes—RGB for screen displays and CMYK for print production. This guide explores their technical differences, practical workflows, and industry standards to help designers achieve precise color management.

1. Core Differences & Working Principles

1.1 Color Mixing Theories

- RGB (Red, Green, Blue)An additive color model where light intensities combine to create colors. Maximum values (255) produce white, making it ideal for self-illuminated devices like monitors and smartphones.

- CMYK (Cyan, Magenta, Yellow, Key/Black)A subtractive model where inks absorb light wavelengths. Cyan, magenta, and yellow theoretically mix to black, but real-world ink limitations require black (K) for true dark tones.

1.2 Gamut Comparison

RGB gamuts (e.g., sRGB covers ~35% of visible spectrum) exceed CMYK’s range (~20-30% for standard printing). This explains why vibrant RGB colors often appear muted when printed. Use Photoshop’s View > Gamut Warning (Ctrl+Shift+Y) to identify out-of-gamut areas (marked by gray overlays).

2. Photoshop Workflow Essentials

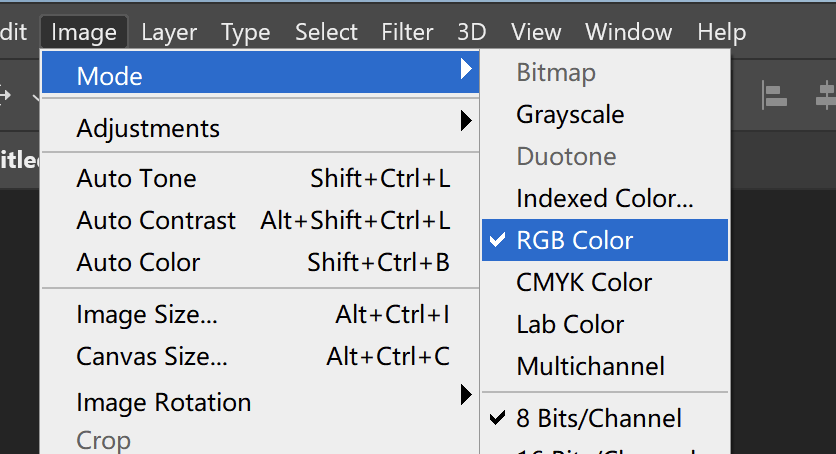

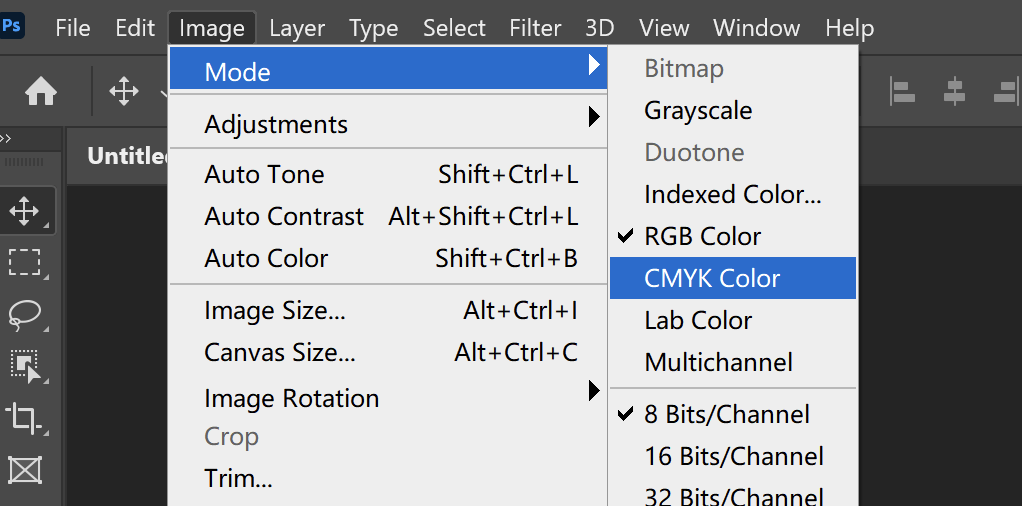

2.1 Document Setup

- RGB ConfigurationDefaults to sRGB IEC61966-2.1 for web design. Professional photography prefers Adobe RGB for wider color range. Access via Edit > Color Settings (Ctrl+Shift+K).

- CMYK ConfigurationUses region-specific profiles like “U.S. Web Coated (SWOP) v2” (North America) or “Japan Color 2001 Coated”. Verify with your printer for custom profiles.

2.2 Color Tools Behavior

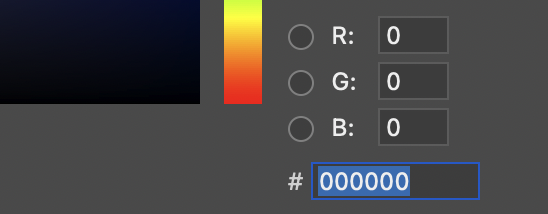

- RGB拾色器 displays 0-255 values; CMYK uses 0-100% ink percentages.

- A yellow warning triangle in the RGB拾色器 indicates unprintable colors. Click to convert to the nearest CMYK-safe equivalent.

3. Application Scenarios

3.1 RGB Use Cases

- Digital Design

- E-commerce product pages

- Social media graphics (Instagram, LinkedIn)

- UI/UX interfaces and app mockups

- Best PracticeAlways retain RGB source files for future edits; convert copies to CMYK for printing.

3.2 CMYK Use Cases

- Print Production

- Packaging designs (cosmetics, food labels)

- Magazines and brochures

- Large-format banners (offset printing)

- Industry StandardLabel files with color mode (e.g., “Summer_Campaign_CMYK.psd”) to prevent workflow errors.

4. Conversion & Color Management

4.1 Safe Conversion Workflow

- Save an RGB backup

- Preview CMYK output via View > Proof Colors (Ctrl+Y)

- Reduce saturation of out-of-gamut areas by 5-10% using Hue/Saturation adjustment layers

- Execute Edit > Convert to Profile (preserves more detail than direct mode change)

4.2 Troubleshooting

- Gamut Issues: Use Lab color mode for adjustments before converting to CMYK

- Color Inconsistencies:

- Calibrate monitors monthly (target 120cd/m² brightness)

- Embed ICC profiles when saving

- Request printer’s ICC profile for soft proofing

5. Professional Best Practices

- Project PlanningDetermine output medium first—start in RGB for digital, CMYK for print-only projects

- Layer ManagementColor-code adjustment layers (e.g., red for CMYK corrections)

- Collaboration

- Provide ICC profiles to printers

- Request press proofs before mass production

- Reference ISO 12647 standards for print quality control

Glossary

- Additive Color Model: Light-based mixing (RGB) where combining primaries creates white

- Subtractive Color Model: Ink/pigment mixing (CMYK) where absorption creates color

- Gamut: Range of colors a device can reproduce

- ICC Profile: File describing a device’s color characteristics

- Rendering Intent: Algorithm for converting colors between gamuts (Perceptual, Saturation, Relative Colorimetric, Absolute Colorimetric)

Comments0